High Quality

Coffee Degassing Valve

from Japan at an Affordable Price

- Easy installation - no machinery required

- Quality assurance performed by high-sensitivity camera inspection

- Significantly lower cost

Enhance product quality and boost efficiency with our coffee degassing valves

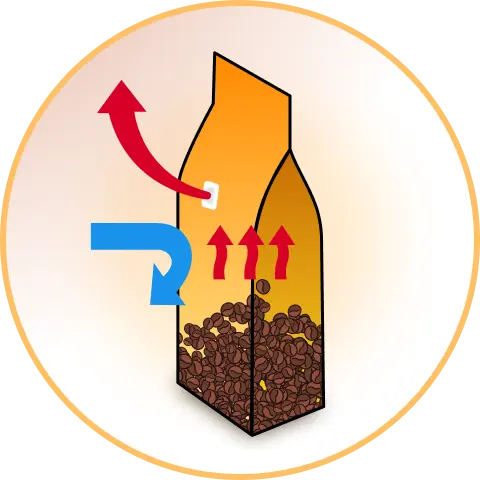

Extend shelf life

Prevent oxidation due to external air and extend the shelf life of coffee by up to one year.

Prevent package ruptures

Allow the gases emitted from roasted coffee to escape, preventing bag bursting and damage.

Increase packaging efficiency

No need to wait for gases to escape post-roasting; making immediate packaging possible.

Premium Japanese Coffee

Degassing Valve

for a Variety of Products

Our degassing valve is designed for easy integration with your products, requiring no special equipment or silicone oil application. Not just for coffee, it's also suitable for other products, including fermented foods like miso, pickles, kimchi, and even animal feed.

Why Choose Our Degassing Valve?

Japan Quality

Made in Japan, with high quality recognized by major café chains and coffee brands

Affordable Price

Lower cost due to integrated production system in our manufacturing plant

Quality Assurance

We ensure high quality products through both camera inspection and manual checking

Easy Installation

No special machinery and no silicone oil application required

Simple Design

Fits a variety of packages in sheet form instead of buttons

Flexible Plans

Various purchase plans available and comprehensive after-sales support

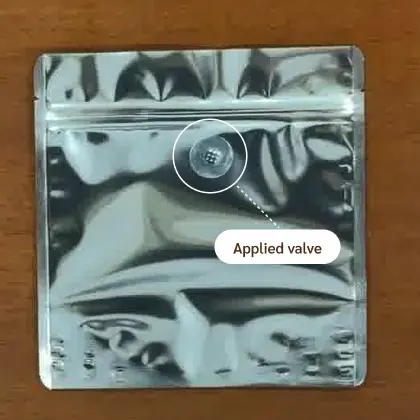

To Install, Simply Affix the Sticker!

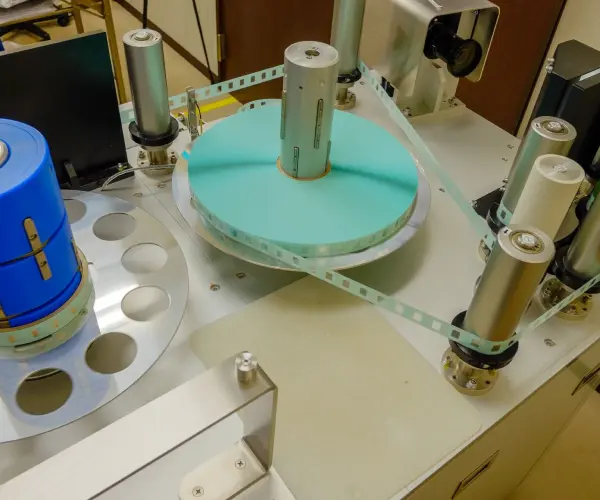

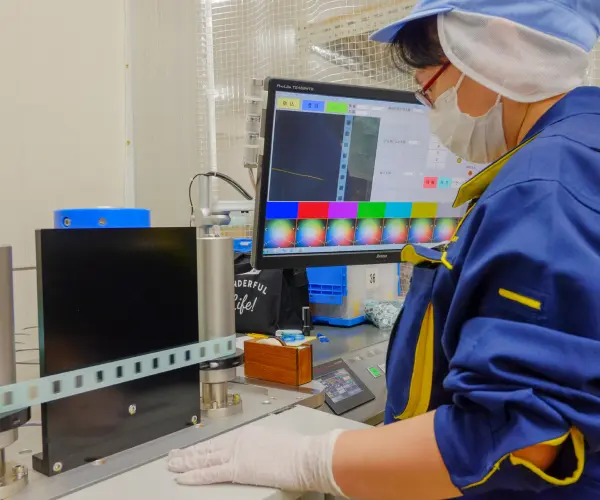

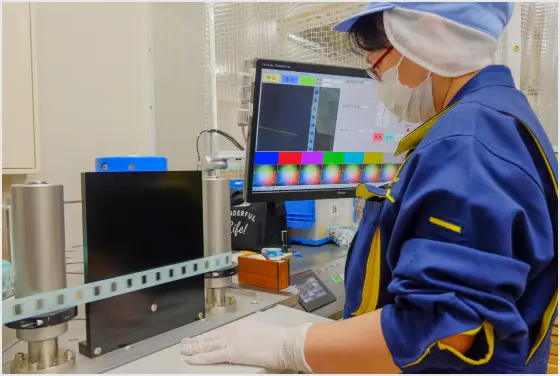

High-sensitivity Camera Inspection

Choose our degassing valve for unmatched quality and value.

Elevate your packaging solutions today.

See how we measure up!

| Outside air infiltration prevention | One-way | ||

| Cost | Very low US$0.02-/unit | High US$0.07-/unit | High US$0.14-/unit |

| Machines required for installation | No special equipment | Require special equipment | Require special equipment |

| Silicone Oil | Already set | Oil application required | No oil needed |

| Duration of effectiveness | About one year | Six-eight months | About one year |

Save over $8,000 each year

with our superior valve solution

*Calculated 200 units per day

Key Features

Special valve stickers made in Japan

A proven solution for long-term preservation, trusted by major coffee shops

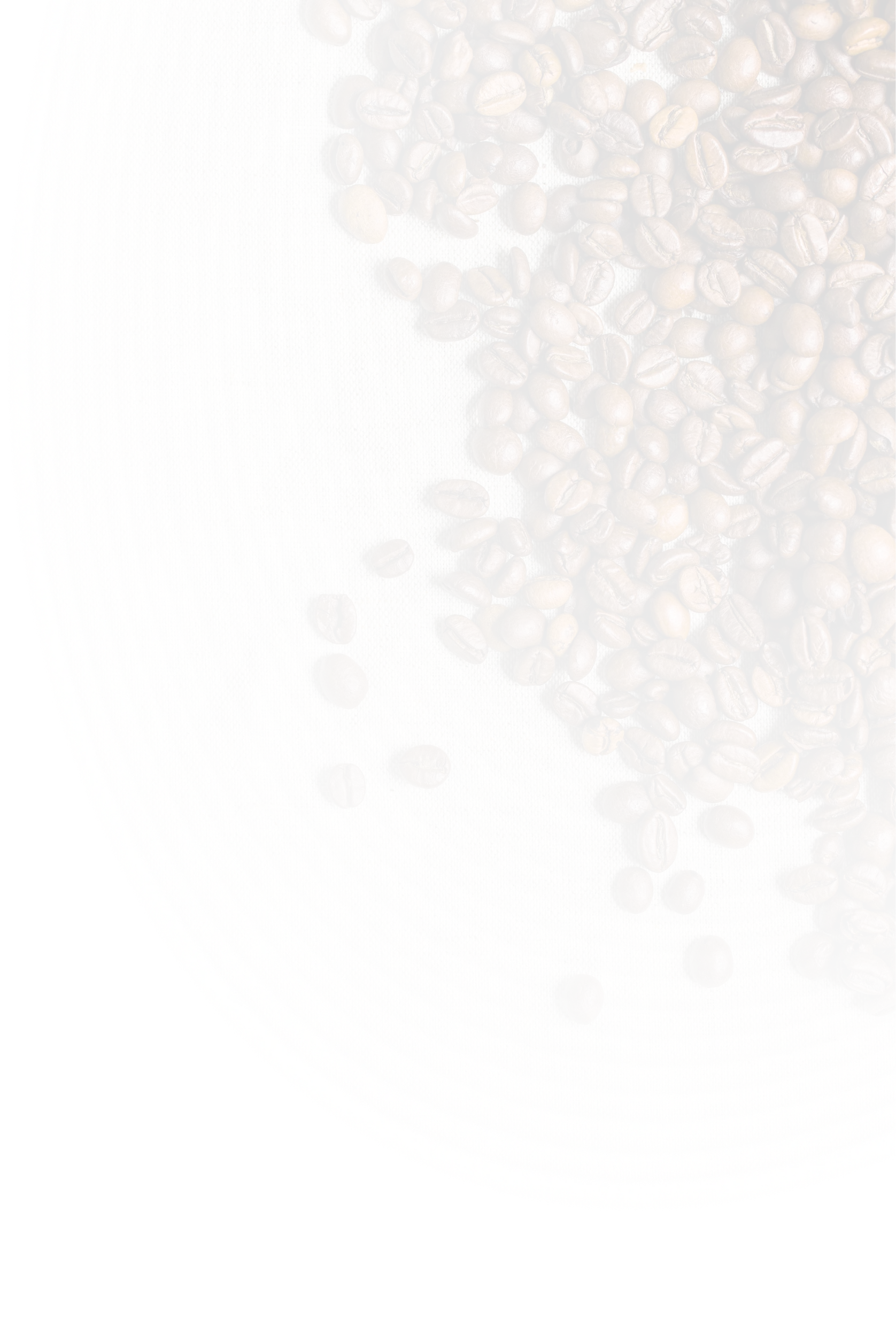

Our valve is designed for fermented food, releasing gases generated within the packaging while preventing external air from entering. It keeps freshly roasted coffee aromatic and delicious over an extended period.

Three-layer valve with silicone oil coating to prevent air infiltration

The inner layer of the valve is coated with silicone oil, allowing the release of accumulated gases within the package while preventing the entry of outside air. Thanks to its three-layer structure, packages with the valve can be closely packed with other items and still effectively release gases.

ISO-certified inspection system

Our inspection system, done by both high-sensitivity camera inspection and human check, is certified with the ISO 9001 Quality Management System and the ISO 22000 Food Safety Management System, both internationally recognized standards.

One-stop shop for production and sales

We handle everything from development to production and sales at our own manufacturing facilities. By selling directly from the manufacturing company, we eliminate intermediate costs, allowing us to offer our products at a significantly lower price compared to other companies.

Product Detail - Our Signature Valve

*MDV-15-125

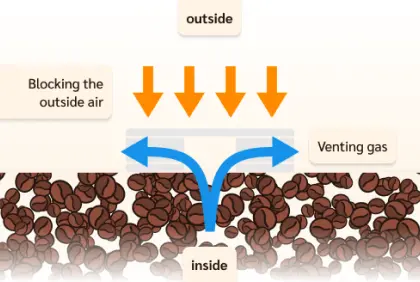

Three-layer structure valve sticker

| Material | Memo | |

|---|---|---|

| Upper Layer | PET125 | Acrylic pressure sensitive adhesive |

| Middle Layer | PET25 | |

| Under Layer | PET100 | |

| Silicone Oil | Manufactured by Shin-Etsu Chemical Co., Ltd. in Japan | Amount applied: 0.0164-0.107/cm² |

| Size | 20mm × 20mm |

| Opening pressure (average) | 80.98mmH2O |

| Closing pressure (average) | 4.0mmH2O |

| Residual oxygen | 0.24%-0.1% |

All base materials used in this product are from Japan, and we can provide MSDS (Material Safety Data Sheet).

The silicone oil used in this product is produced in accordance with Japan's Food Sanitation Law.

Lower priced two-layer structure valve is also available.

Installation Process (Manual)

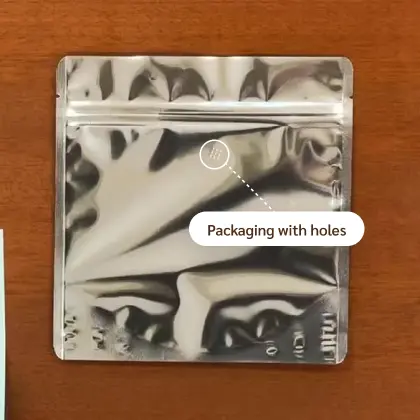

Step 1

Prepare our valve and a product packaging with holes.

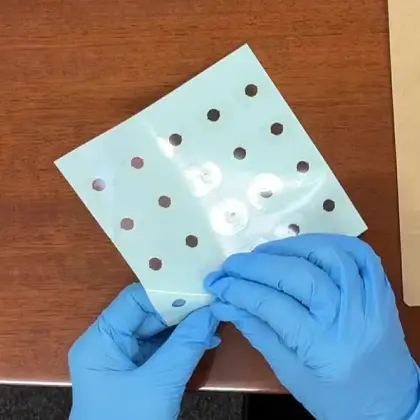

Step 2

Peel off the valve from the backing paper.

Step 3

Attach the valve to the hole in the packaging.

Step 4

Done!

If you plan to apply more than 100 valves a day, using dedicated machinery is recommended for efficiency.

We can also provide these specialized machines, so please feel free to inquire if interested.

Flow of Delivery

*Samples can be provided.

*Possible to measure the effect of oxidation concentration after your company's introduction.

Company Profile

Maruten co., Ltd.

丸天産業株式会社

Head Office

Japan

President

Hiroyuki Sato

Locations

Three locations in Japan (Hiroshima, Tokyo and Osaka)

Services

Seal, label printing and related materials sales, incidental business

Founded

1973

Authorization

ISO9001, ISO22000, Japan Food Packaging Association

Established in 1973, Maruten Sangyo Co., Ltd. began as a food label printing and manufacturing company, diversifying into seal labels and specialized printing for various industries. Our "Made in Japan" quality and efficient production process, from order receipt to shipping, have garnered recognition globally.

We're also proud to offer our own brands, including the "ROUND TOP" stationery line and the "TASTE KEEP VALVE" coffee valve series

Contact Us

We can propose the best purchase plan according to a company’s specific scale of production from large coffee chains to small stores. Contact us for a consultation today.